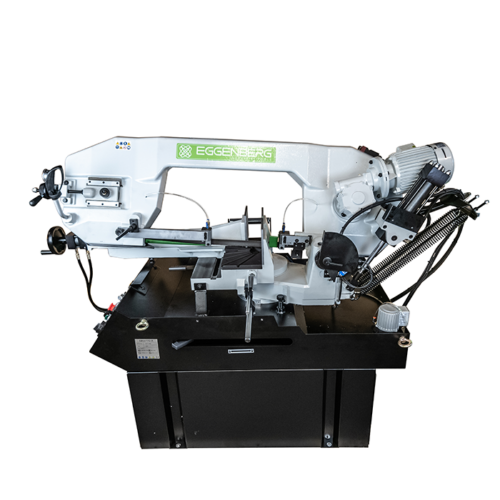

Paton ProMIG 200 15-2 MIG/MAG welder - MMA/TIG + 4M welding torch Abicor Binzel

Features Paton ProMIG 200 15-2 MIG/MAG welder - MMA/TIG + 4M welding torch Abicor Binzel

The Paton ProMIG 200 Welding machine is designed for semi-automatic MIG/MAG-Welding with shielding gases and protective mixtures, hand arc MMA-welding and argon protection TIG-welding with direct current.

The design of the ProMIG 200-model (coil of 15 kg, also suitable for a coil of 5 kg - supply of 2 coils) offers one of the best protection against external influences on the market. The rated current of this model of 200 A at a duty cycle of 70% is a result that allows intensive welding of 6 mm materials without risk of overheating. The power source can be separated from the welding wire feed mechanism for ease of use and safety. Features of the semi-automatic welding machines of the PATON™ Professional Series are the high-quality sealed metal wire feed, and the existing KZ-2 "EURO" type connector, which has become a standard worldwide, allowing the user to change the handle at will in the future.

In a fully electronic system, the control system absolutely disposes of all the resources of the source, within the limits of its full power and regardless of the method used. The "Professional" series device is intended for industrial use, for the most demanding users.

Features

GAS-FREE WELDING - WELDING WITH SELF-CONSUMING WIRE

All PATON MIG/MAG welding machines are adapted for welding with self-protected wire. This welding, unlike traditional MIG/MAG welding, is performed without using shielding gas - however, it requires a special welding wire. The wire produces its own shielding which helps to protect the welding arc. Self-protecting wire suitable for PATON welding machines can be bought here - spools of 5 kg of wire fit all wire feeders.

SOLDERING - INDUCTANCE ADJUSTMENT

Paton MIG/MAG welders of the Standard and PRO series have brazing capabilities thanks to the three-step inductance change function. Thanks to inductance control, the arc characteristics can be optimised according to the thickness of the part to be welded. This function is needed to change the speed of the current when the arc voltage is changed. The thinner the part to be welded by MIG/MAG, the higher the induction should be (soft arc - less melting), for thicker parts the opposite (hard arc - more melting).

PULSE FUNCTION IN ALL METHODS

- PULSE in TIG welding - Full control of the heat entering the material - a great feature for welding stainless steels and acid-resistant steels,

- PULSE in MMA - easier transfer of material from electrode to weld pool, better quality of welded joint,

- Pulses in MIG/MAG welding - easier release of metal droplets from the end of the electrode wire, ability to adjust pulse current parameters. MIG welding with pulse is useful for welding stainless steels, acid-resistant steels and aluminium alloys. Moreover, pulse welding offers better parameters for brazing CuSi3

MAIN DIFFERENCES BETWEEN STANDARD AND PRO SERIES MIG/MAG WELDING MACHINES

- duty cycle - PRO series MIG/MAG welders have a duty cycle of 70%, while the standard series has a duty cycle of 45% at the same welding current. Moreover, PRO series MIG/MAG welders achieve continuous duty cycle at a higher welding current than the standard series.

- Wire feeder - in the PRO series, there is a separate wire feeder that can handle coils of 15 to 18 kg. The feed can be separated from the source for convenience when welding other methods - such as MMA or TIG DC. The PRO series also has wire feeder versions with 2 coils or with 4 coils. In Standard series MIG/MAG welding machines, the wire feed unit is built into the welding unit, supports only spools up to 5 kg and always has two rollers.

What are the main benefits?

- European production

- Electronic thermal protection system that protects all heat-producing elements from overheating

- Reliability thanks to IGBT technology

- Ability to work with long extension cables and with a generator

- Pulse current welding in any welding method

- Improved arc glow stability

- Change mode function 2T, 4T, gas purge feeder function

- The devices are equipped with a system for protection against voltage spikes and stabilisation, allowing proper operation in the voltage range 160V to 260V

- Twice less power consumption compared to traditional sources

- Optimal melting and correct pitch shape, regardless of welding position

Scope of delivery

- Paton ProMIG 200 15-2 MIG/MAG welder - MMA/TIG

- PATON™ BPI 15-2 feeder (15 kg spool, also supports 5 kg spool - 2 rolls of feeder)

- MIG MAG welding gun ABICOR BINZEL MB GRIP 15 4m

- Electrode holder ABICOR BINZEL DE2200 3m

- Bulk holder ABICOR BINZEL MK300 3m

- Wire feed rollers 1x (0.6 - 0.8), 1x (1.0 - 1.2) V

- Welding wire coil cover

- Quick coupling for gas

- Cardboard packaging

- Carrying strap

- User manual

Documents

| Brand | Paton |

|---|---|

| Type of product | MIG welding machine, MIG/MAG welding machine, MMA welding machine, TIG welding machine |

Reviews

There are no reviews yet.